4l60e manual

The 4L60E is a widely used automatic transmission known for reliability and durability‚ employed in various GM vehicles. It features electronic controls for smooth gear shifting and enhanced performance. This manual provides essential insights for professionals and DIY enthusiasts‚ covering rebuilds‚ repairs‚ and maintenance. It includes detailed procedures‚ torque specs‚ and troubleshooting guides‚ ensuring a comprehensive understanding of the transmission system.

1.1 Overview of the 4L60E Transmission

The 4L60E is a versatile‚ electronically controlled automatic transmission designed for rear-wheel-drive vehicles. Known for its reliability and durability‚ it is widely used in GM trucks‚ SUVs‚ and performance cars. This transmission features four forward gears‚ an overdrive‚ and a lockup torque converter‚ making it suitable for both towing and everyday driving. Its electronic controls optimize shifting patterns for improved performance and fuel efficiency.

1.2 Importance of the 4L60E Manual

A comprehensive 4L60E manual is essential for technicians and enthusiasts‚ offering detailed instructions for repair‚ overhaul‚ and maintenance. It provides torque specs‚ exploded views‚ and step-by-step procedures‚ ensuring accurate and safe servicing. The manual also covers diagnostic techniques‚ shift patterns‚ and electronic controls‚ making it an indispensable resource for understanding and maintaining the transmission’s optimal performance and longevity.

Identification and Specifications

The 4L60E transmission can be identified by its distinctive 13 bolt pan‚ case markings‚ and electrical connectors. Key specifications include a 3.059:1 first gear ratio and 0.70:1 overdrive‚ with a maximum fluid capacity of approximately 10 quarts. These details are crucial for proper identification and ensuring compatibility in various vehicle applications.

2.1 How to Identify a 4L60E Transmission

The 4L60E can be identified by its 13-bolt pan‚ specific case markings‚ and electrical connectors. It features a unique bellhousing pattern and torque converter setup. The transmission case often has identifying codes or stamps‚ such as “4L60E” or a specific serial number range. These characteristics‚ along with its electronic control features‚ distinguish it from other GM transmissions like the 4L60 or 4L80E.

2.2 Key Specifications and Features

The 4L60E is a four-speed automatic transmission with an overdrive gear. It features a lock-up torque converter‚ electronic controls for adaptive shifting‚ and a robust gearset designed for moderate to heavy-duty applications. The transmission’s compact design allows it to fit various GM vehicles‚ with a max torque capacity of 360 lb-ft. It is known for its reliability and versatility across different engine configurations and vehicle types.

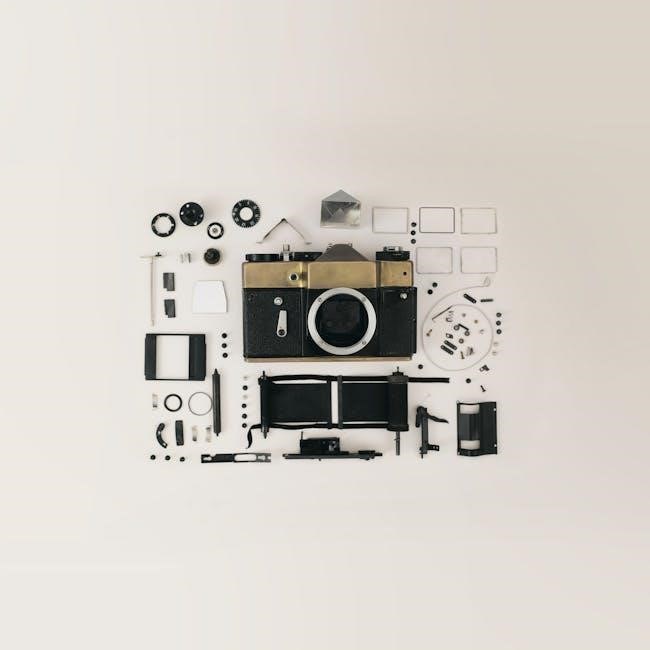

Components and Parts

The 4L60E transmission consists of a torque converter‚ gearset‚ valve body‚ and electronic control module. Key components include the pump‚ planetary gears‚ and clutch packs. Proper maintenance of these parts ensures optimal performance and longevity.

3.1 Major Components of the 4L60E

The 4L60E transmission comprises several critical components‚ including the torque converter‚ which transfers engine power to the transmission‚ and the gearset‚ responsible for providing various gear ratios. The valve body directs fluid flow to engage gears‚ while the electronic control module manages shift patterns. Additionally‚ the transmission features planetary gears‚ clutch packs‚ and a pump to circulate hydraulic fluid‚ ensuring smooth operation. Regular maintenance of these parts is crucial for optimal performance and longevity.

3.2 Essential Parts for Rebuild and Repair

The 4L60E rebuild requires gaskets‚ seals‚ bearings‚ and bushings to prevent leaks and wear. Clutch packs‚ steels‚ and planetary gears ensure smooth engagement and durability. The input and output shafts are critical for power transfer. A transmission overhaul kit‚ including these parts‚ is essential. Regularly replacing the filter ensures clean fluid circulation‚ prolonging transmission life and maintaining optimal performance.

Torque Specifications

Torque specifications for the 4L60E are crucial for proper reassembly and installation‚ ensuring durability and performance. Bolt torque values are precisely outlined to avoid damage and maintain reliability.

4.1 Bolt Torque Specifications for Reassembly

Accurate bolt torque specifications are essential for the 4L60E reassembly to ensure structural integrity and prevent damage. Valve body bolts typically require 10-12 ft-lbs‚ while pan bolts need 8-10 ft-lbs. Proper torque sequences must be followed to avoid warping components. Always refer to the manual for specific values‚ as incorrect torque can lead to transmission case damage during reassembly procedures.

4.2 Proper Torque Values for Installation

Proper torque values ensure secure installation without damaging components. Transmission pan bolts typically require 8-10 ft-lbs‚ while valve body bolts need 10-12 ft-lbs. Ensure correct bolt length and sequence to avoid warping. Always use a torque wrench for accuracy. Incorrect torque can lead to leaks or internal damage. Refer to the manual for specific values to guarantee a safe and reliable installation process.

Overhaul and Rebuild Procedures

The 4L60E manual provides a comprehensive guide for transmission overhaul and rebuild procedures‚ suitable for both professionals and DIY enthusiasts. It outlines a systematic approach to ensure reliability and performance after rebuild‚ emphasizing precision and adherence to detailed instructions.

5.1 Step-by-Step Rebuild Process

The 4L60E rebuild process begins with disassembly‚ removing the torque converter‚ valve body‚ and internal components. Inspect and replace worn parts‚ such as bearings and seals. Reassemble using specified torque values and ensure proper alignment. Install the valve body and manual valve link‚ followed by the torque converter. Final steps include fluid refill and testing to ensure smooth operation and functionality across all gears.

5.2 Special Tools and Equipment Required

Specialized tools are essential for a successful 4L60E rebuild; A torque wrench ensures precise bolt tightening‚ while a dial indicator aids in component alignment. A bearing puller and transmission pan gasket are crucial for disassembly and reassembly. Additionally‚ the ATSG manual provides detailed repair procedures and specifications‚ making it indispensable for both professionals and DIY enthusiasts. Proper equipment guarantees accuracy and prevents damage.

Common Issues and Troubleshooting

Common issues include slipping‚ harsh shifting‚ and bind-ups in manual modes. Causes often involve worn clutch packs‚ faulty sensors‚ or fluid contamination. Refer to diagnostic guides for troubleshooting solutions.

6.1 Common Problems with the 4L60E

The 4L60E often experiences issues like slipping between gears‚ harsh shifts‚ and failure to engage gears. These problems can stem from worn clutch packs‚ faulty solenoids‚ or low transmission fluid levels. Additionally‚ electronic control system malfunctions and torque converter damage are common‚ requiring careful diagnosis and repair to restore proper function and prevent further damage.

6.2 Diagnostic Techniques and Solutions

Diagnosing 4L60E issues involves using a scan tool to read error codes‚ checking transmission fluid levels‚ and inspecting wiring harnesses. Common solutions include replacing faulty solenoids‚ repairing or replacing the torque converter‚ and updating transmission software. Proper testing ensures accurate identification of problems‚ while systematic repairs restore functionality and prevent recurring issues.

Electronic Controls and Shift Patterns

The 4L60E features advanced electronic controls for precise shift patterns and adaptive learning‚ ensuring smooth gear transitions. This system is thoroughly explained in the manual for optimal performance and customization.

7.1 Understanding Electronic Controls

The 4L60E employs an advanced electronic control system‚ utilizing sensors and solenoids to regulate shift patterns and torque delivery. This setup ensures adaptive learning‚ optimizing performance based on driving conditions. The system integrates with the vehicle’s PCM‚ enabling real-time adjustments for smooth operation. Understanding these controls is crucial for diagnostics and custom tuning‚ as detailed in the manual.

7.2 Shift Patterns and Adaptive Learning

The 4L60E features adaptive learning‚ enabling it to adjust shift patterns based on driving habits and conditions. The ECM monitors throttle position‚ vehicle speed‚ and engine load to optimize shifts. Over time‚ the transmission “learns” the driver’s style‚ improving responsiveness and efficiency. Adaptive learning ensures smoother transitions and better fuel economy‚ adapting to both aggressive and conservative driving behaviors effectively.

Maintenance and Service

Regular maintenance is crucial for the 4L60E’s longevity. This includes fluid changes‚ filter replacements‚ and checking for wear. Adhering to the schedule prevents premature wear and ensures optimal performance.

8.1 Regular Maintenance Schedule

A well-structured maintenance schedule ensures the 4L60E operates efficiently. Fluid checks every 15‚000 miles and filter replacements at 30‚000 miles are recommended. Inspecting cooler lines‚ pan gaskets‚ and seals annually prevents leaks. Monitoring transmission temperature and performance during driving helps identify issues early. Following GM’s guidelines ensures longevity and optimal functionality of the transmission system. Regular maintenance is key to preventing costly repairs and ensuring smooth operation.

8.2 Fluid Change and Filter Replacement

Changing the transmission fluid and replacing the filter are crucial for maintaining the 4L60E’s health. Use only GM-approved fluid to ensure compatibility. Replace the filter every 30‚000 miles or as needed. Draining the old fluid and installing a new filter prevents contamination and wear. Proper disposal of used materials is essential. Always refer to the service manual for precise instructions and torque specifications to avoid damage during the process.

Rebuild and Repair Manuals

The 4L60E rebuild and repair manuals are downloadable PDFs‚ providing detailed procedures for professionals and DIYers. They cover essential steps for successful transmission overhauls and maintenance.

9.1 Downloadable PDF Resources

Downloadable PDF manuals for the 4L60E transmission are widely available‚ offering detailed rebuild procedures‚ torque specifications‚ and exploded parts views. Resources include the ATSG manual‚ Hydra-matic 4L60-E Technicians Guide‚ and comprehensive user guides. These PDFs are essential for professionals and DIY enthusiasts‚ providing step-by-step instructions for successful transmission overhauls‚ repairs‚ and maintenance. They can be found online through various transmission repair websites and forums.

9;2 Recommended Technician Guides

For professional repair‚ the ATSG 4L60-E manual and Hydra-matic Technicians Guide are highly recommended. These resources provide detailed procedures‚ torque specifications‚ and troubleshooting tips. The ATSG manual includes electronic controls and shift patterns‚ while the Hydra-matic guide covers service‚ diagnosis‚ and repair. These comprehensive guides are essential for technicians and can be found on reputable transmission repair websites and forums.

Valve Body Removal and Installation

Remove the manual valve link and note check ball locations to avoid loss. Lift the valve body carefully‚ ensuring bolts are correctly positioned to prevent transmission case damage.

10.1 Proper Techniques for Valve Body Service

When servicing the valve body‚ disconnect the manual valve link and carefully lift to avoid losing check balls. Note bolt lengths and positions to prevent case damage. Use a torque wrench for secure reinstallation. Ensure all connections are tight and aligned properly to maintain transmission performance and prevent leaks or mechanical failure during operation.

10.2 Avoiding Common Mistakes

Common mistakes during valve body service include losing check balls‚ misaligning components‚ and incorrect bolt torque. Always note bolt positions and lengths to prevent case damage. Ensure the manual valve link is properly disconnected and reconnected. Use correct tools to avoid stripping threads. Double-check all connections before reassembly to maintain proper transmission function and prevent costly repairs or premature failure.

Transmission Overhaul Kits

A transmission overhaul kit includes gaskets‚ seals‚ bearings‚ and clutch packs. Use high-quality components and follow manufacturer guidelines for best results and durability.

11.1 What to Include in an Overhaul Kit

An overhaul kit for the 4L60E should include gaskets‚ seals‚ bearings‚ clutch packs‚ and steel plates. Ensure all components are high-quality and specific to the 4L60E. Use manufacturer guidelines to verify compatibility and avoid mismatches. Include a detailed parts list and consult a parts manual for specific requirements. Proper kit assembly ensures durability and optimal transmission performance after rebuild.

11.2 Best Practices for Kit Assembly

Organize all parts before starting and cross-reference them with the overhaul kit list. Use torque specifications from the manual to ensure proper bolt tightening. Clean all components thoroughly before installation to prevent contamination. Follow the step-by-step rebuild guide for correct assembly order. Double-check each step to avoid mistakes. Use specialized tools as recommended for precise adjustments and secure connections.

User Manuals and Resources

Downloadable PDF resources like the 4L60E rebuild manual and service guides provide detailed instructions. Technician guides and comprehensive user manuals ensure proper understanding and maintenance of the transmission system.

12.1 Comprehensive User Guides

Comprehensive user guides for the 4L60E transmission are available in downloadable PDF formats‚ offering detailed instructions for rebuilds‚ repairs‚ and maintenance. These guides include step-by-step procedures‚ torque specifications‚ and troubleshooting tips. They cover electronic controls‚ shift patterns‚ and adaptive learning features. Additionally‚ they provide insights into transmission operation‚ diagnostic techniques‚ and best practices for servicing. These resources are essential for technicians and DIY enthusiasts alike‚ ensuring proper understanding and efficient servicing of the 4L60E transmission.

12.2 Additional Resources for Repair and Maintenance

For comprehensive repair and maintenance‚ additional resources like the ATSG manual and Hydra-matic Technician Guides provide detailed insights. These include exploded parts views‚ torque specs‚ and overhaul procedures. Websites offer free PDF downloads‚ such as a 150-page service manual and a 186-page rebuild guide. These resources cover electronic controls‚ shift patterns‚ and adaptive learning‚ ensuring a thorough understanding of the 4L60E transmission system for effective servicing and troubleshooting.

Final Checks and Test Driving

Post-rebuild inspection ensures all components are properly installed and functioning. Test driving confirms smooth shifting‚ proper engagement‚ and overall transmission performance‚ validating the repair’s success and reliability.

13.1 Post-Rebuild Inspection Checklist

A thorough post-rebuild inspection is crucial. Check for proper torque converter installation‚ ensure all bolts are tightened to specifications‚ and verify fluid levels. Inspect the valve body‚ solenoids‚ and wiring connections for damage or leaks. Test the manual valve linkage and ensure all electrical connectors are securely attached. Perform a visual check for any signs of damage or wear on components like the pump‚ planetaries‚ and bearings. Ensure the transmission pan is securely fastened‚ and all gaskets are properly seated to prevent leaks. Verify that the cooler lines are connected correctly and not obstructed. Finally‚ check the transmission control module (TCM) for any error codes using a scan tool to ensure electronic controls are functioning correctly. Address any issues before test driving to ensure safety and optimal performance.

13.2 Test Driving to Ensure Proper Function

After the rebuild‚ conduct a thorough test drive to verify proper transmission function. Start with a slow drive to check smooth shifting through all gears. Accelerate gradually to ensure no slipping or harsh engagements. Test in both automatic and manual modes‚ monitoring for any unusual behavior; Check for proper torque converter engagement and smooth deceleration. Ensure electronic controls and adaptive learning functions operate correctly‚ and verify there are no error codes using a scan tool. A successful test drive confirms the transmission is functioning as intended‚ ready for reliable performance.

Leave a Reply

You must be logged in to post a comment.