hvac layout plan pdf

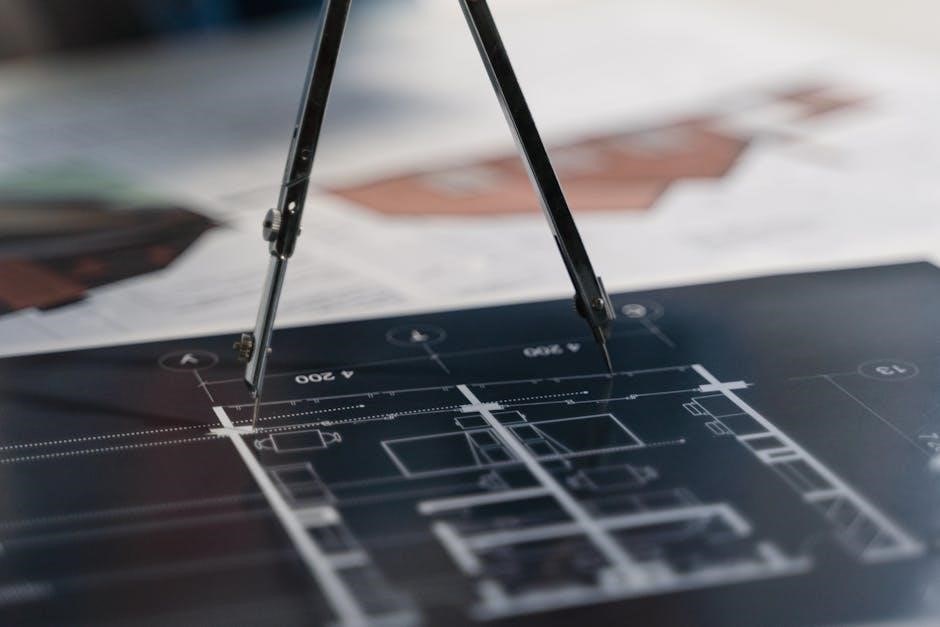

An HVAC layout plan visually represents the placement and design of heating, ventilation, and air-conditioning systems in a building, ensuring efficient installation, maintenance, and regulatory compliance.

1.1 What is an HVAC Layout Plan?

An HVAC layout plan is a detailed schematic representation of a building’s heating, ventilation, and air-conditioning system. It illustrates the placement of equipment, ductwork, and vents, ensuring efficient airflow and climate control. The plan is essential for installing, maintaining, and upgrading HVAC systems, providing a clear visual guide for architects, engineers, and contractors. It is typically included in a building’s blueprints and is crucial for ensuring system performance, energy efficiency, and compliance with safety standards.

1.2 Importance of HVAC Layout Plans in Building Design

HVAC layout plans are crucial for ensuring efficient heating, cooling, and ventilation in buildings. They guide the installation of equipment, ductwork, and vents, ensuring proper airflow and climate control. These plans help architects and engineers design energy-efficient systems, reduce operational costs, and meet building codes. They also facilitate maintenance and upgrades, ensuring long-term performance. A well-designed HVAC layout plan enhances indoor air quality, occupant comfort, and overall building functionality, making it a cornerstone of modern building design and construction.

Key Elements of an HVAC Layout Plan

An HVAC layout plan includes ductwork, vents, equipment locations, and airflow pathways, ensuring efficient heating, cooling, and ventilation while meeting building codes and design requirements.

2.1 Components of HVAC Systems

An HVAC system comprises heating, ventilation, and air-conditioning units, including furnaces, heat pumps, condensers, and air handlers. Ductwork, vents, and grilles distribute conditioned air, while thermostats regulate temperatures. The layout plan details the placement of these components, ensuring proper airflow and system efficiency. It also includes electrical connections, controls, and insulation, which are critical for performance. Accurate representation of these elements in the plan ensures seamless installation and operation, meeting both functional and regulatory requirements.

2.2 Symbols and Notations Used in HVAC Plans

HVAC plans use standardized symbols and notations to represent components like air handlers, ducts, vents, and thermostats. Common symbols include FCU (fan coil unit) and ACU (air conditioning unit). These notations ensure clarity and consistency, aiding technicians in understanding system layouts. Ductwork is often marked with arrows indicating airflow direction, while vents are labeled with sizes and types. Proper use of these symbols ensures accurate installation and compliance with design specifications, making the plan a critical reference for engineers and installers.

2.3 Floor Plan Integration with HVAC Layout

Integrating HVAC layouts with floor plans ensures systems are seamlessly incorporated into building designs. This process involves placing ducts, vents, and equipment in non-occupiable spaces like ceilings or basements. Proper integration avoids conflicts with structural elements and maintains aesthetic appeal. By aligning HVAC components with room layouts, engineers optimize airflow and energy efficiency. This integration is crucial for both residential and commercial projects, ensuring systems operate effectively while remaining inconspicuous. Accurate placement is verified through detailed drawings and on-site inspections to meet design and functional requirements.

Design Considerations for HVAC Layout Plans

Designing HVAC layouts requires balancing efficiency, cost, and space. Load calculations, ductwork optimization, and zoning systems are key to ensure optimal heating, cooling, and ventilation performance.

3.1 Load Calculations and System Sizing

Load calculations are critical for determining the heating and cooling demands of a building. Factors like insulation, window placement, and occupancy levels influence these calculations. Accurate sizing ensures systems operate efficiently without excess energy use. Proper sizing also prevents equipment short-cycling and maintains consistent indoor air quality. Using specialized software, engineers analyze these factors to design systems that meet specific load requirements. This step ensures the HVAC layout plan is both functional and energy-efficient, aligning with sustainability goals and reducing long-term operational costs.

3.2 Ductwork and Ventilation Design

Ductwork and ventilation design are essential for distributing conditioned air efficiently throughout a building. Properly sized ducts minimize energy losses and ensure consistent airflow. Insulated ducts reduce heat gain or loss, while sealed connections prevent leaks. Ventilation systems must meet indoor air quality standards, incorporating fresh air intake and exhaust strategies. Designing duct layouts requires balancing system performance, space constraints, and noise reduction. Compliance with local building codes ensures safety and efficiency, making ductwork a critical component of HVAC layout plans.

3.3 Zoning Systems for Efficient Heating and Cooling

Zoning systems divide a building into independent temperature zones, enhancing comfort and energy efficiency. By using dampers and thermostats, zones regulate airflow and heating/cooling demands. This reduces energy waste by avoiding conditioning unoccupied areas. Zoning systems integrate seamlessly with ductwork, ensuring precise control. They are ideal for buildings with varying occupancy patterns or multiple uses. Proper zoning design balances system performance, user comfort, and energy savings, making it a key feature in modern HVAC layout plans for both residential and commercial spaces.

Tools and Software for Creating HVAC Layout Plans

CAD software, BIM tools, and specialized HVAC design programs enable precise layout creation, simulations, and compliance with building standards, streamlining the design process for engineers and architects.

4.1 CAD Software for HVAC Design

CAD software is essential for creating detailed HVAC layout plans, offering precise drafting tools for ductwork, equipment placement, and system simulations. Programs like AutoCAD and Revit enable engineers to design efficient heating, ventilation, and cooling systems, ensuring proper airflow and energy efficiency. These tools also facilitate collaboration with architects and contractors, integrating HVAC designs seamlessly into overall building plans. By leveraging CAD, professionals can produce accurate, scalable, and compliant layouts, streamlining the design process and improving project outcomes.

4.2 BIM (Building Information Modeling) Tools

BIM tools enhance HVAC design by providing a collaborative, data-rich environment for creating and managing building systems. Software like Revit and Navisworks allow engineers to integrate HVAC layouts with architectural and structural elements, ensuring compatibility and efficiency. BIM facilitates real-time updates, clash detection, and energy analysis, improving project accuracy and reducing errors. By utilizing BIM, professionals can optimize system performance, streamline workflows, and deliver sustainable, high-performance buildings, making it a cornerstone of modern HVAC design and construction processes.

4.3 Specialized HVAC Design Software

Specialized HVAC design software, such as AutoCAD, Revit, and HVAC-specific tools like Trane’s TRACE or Carrier’s HAP, streamlines the creation of detailed HVAC layout plans. These programs offer advanced features like 2D and 3D modeling, duct sizing, and load calculations, ensuring precise system design. They also support energy efficiency analysis and compliance with building codes. By automating complex tasks, these tools enhance accuracy, reduce design time, and improve collaboration among engineers and architects, making them indispensable for modern HVAC projects and ensuring optimal system performance.

Best Practices for HVAC Layout Plan Development

Adhering to building codes, optimizing energy efficiency, and fostering collaboration between architects and engineers are key best practices for developing effective HVAC layout plans, ensuring functionality and sustainability.

5.1 Compliance with Building Codes and Regulations

Ensuring HVAC layout plans comply with local building codes and regulations is crucial for legal adherence and safety. This involves proper placement of equipment, ductwork, and ventilation systems to meet fire safety, energy efficiency, and accessibility standards. Compliance also ensures that the system operates within acceptable noise levels and maintains indoor air quality. Regular inspections and certifications are necessary to validate adherence to these regulations, avoiding potential fines and ensuring a safe, functional environment for occupants.

5.2 Energy Efficiency Considerations

Energy efficiency is a critical factor in HVAC layout plans, focusing on minimizing energy consumption while maintaining comfort. This involves optimizing ductwork layouts to reduce heat loss, selecting high-efficiency equipment, and incorporating smart technologies. Proper insulation, sealing, and zoning systems also play key roles in reducing energy waste. By adhering to energy-efficient design principles, HVAC systems can lower operational costs and contribute to sustainable building practices, aligning with environmental goals and reducing carbon footprints.

5.3 Collaboration Between Architects and HVAC Engineers

Effective collaboration between architects and HVAC engineers ensures seamless integration of heating, ventilation, and air-conditioning systems into building designs. Architects provide spatial and aesthetic requirements, while engineers optimize system performance and energy efficiency. Early communication helps identify potential challenges, such as ductwork placement and equipment locations, ensuring both functional and visually appealing outcomes. This teamwork is essential for creating balanced, efficient, and sustainable buildings that meet both design and operational goals, enhancing overall occupant comfort and satisfaction.

Common Mistakes to Avoid in HVAC Layout Plans

Avoiding oversizing or undersizing equipment, poor duct insulation, and incorrect placement of air handling units ensures efficient system performance and prevents energy waste and discomfort.

6.1 Oversizing or Undersizing HVAC Equipment

Oversizing or undersizing HVAC equipment is a common mistake that leads to inefficiency and discomfort. Oversized systems may short cycle, reducing humidity control and lifespan, while undersized systems struggle to meet demand. Proper load calculations and consideration of building use are crucial to select appropriately sized equipment, ensuring optimal performance, energy efficiency, and occupant satisfaction. Always refer to ASHRAE standards and consult with professionals to avoid these costly errors in HVAC layout plans.

6.2 Inadequate Duct Insulation and Sealing

Inadequate duct insulation and sealing are common issues that lead to energy loss and reduced HVAC system efficiency. Poorly insulated ducts can lose heat in winter and gain heat in summer, increasing energy consumption. Leaks in ductwork allow conditioned air to escape, lowering system performance and raising utility bills. Proper insulation and sealing are essential to maintain consistent indoor air quality and ensure the HVAC system operates efficiently. Regular inspections and maintenance can prevent these issues in HVAC layout plans.

6.3 Poor Placement of Air Handling Units

Poor placement of air handling units (AHUs) can significantly impact HVAC system performance and efficiency. Incorrect positioning may lead to uneven airflow distribution, increased energy consumption, and higher maintenance costs. AHUs should be strategically located to ensure proper air circulation and minimize ductwork complexity. Placing them too far from service areas or in inaccessible locations can complicate repairs and reduce system effectiveness. Proper placement is crucial for maintaining optimal indoor air quality and operational efficiency in HVAC layout plans.

Case Studies of Effective HVAC Layout Plans

Case studies demonstrate successful HVAC layouts, showcasing efficient system designs, energy savings, and improved indoor air quality in residential, commercial, and industrial settings through real-world examples.

7.1 Residential HVAC Layout Examples

Residential HVAC layouts often feature compact ductwork and zoned systems, ensuring efficient heating and cooling. Examples include single-story homes with centralized units and multi-level designs using split systems. These plans emphasize space-saving solutions, such as ducts in attics or crawl spaces, and integrate with floor plans to maintain aesthetics. Energy efficiency is a key focus, with proper insulation and smart thermostats. Case studies highlight how these layouts improve comfort and reduce energy costs for homeowners.

7.2 Commercial HVAC Layout Examples

Commercial HVAC layouts are designed for larger spaces, ensuring efficient climate control and air quality. Examples include office buildings with rooftop units and malls using large ductwork. These systems often feature zoning to manage different areas’ needs, such as varying temperatures in open spaces versus individual offices. Energy efficiency is prioritized through advanced technologies like variable air volume systems. Proper placement of mechanical rooms and ventilation shafts is crucial for maintaining aesthetics and functionality. These layouts are tailored to meet high occupancy demands and operational requirements.

7.3 Industrial HVAC Layout Examples

Industrial HVAC layouts are designed for large-scale facilities like factories, warehouses, and manufacturing plants. These systems often feature heavy-duty ductwork, exhaust ventilation, and robust air handling units to manage high heat loads and airborne contaminants. The layouts prioritize energy efficiency and durability, with components like large rooftop units and industrial-grade filters. They are tailored to maintain precise temperature and humidity levels, ensuring optimal working conditions and equipment longevity. Customized zoning systems are commonly used to address specific operational needs in different areas of the facility.

Resources for HVAC Layout Plan Templates

Resources for HVAC layout plans include free and paid templates available online. Microsoft offers various tools, while specialized platforms provide downloadable plans for industrial and commercial use.

8.1 Free HVAC Layout Plan Templates

Free HVAC layout plan templates are widely available online, offering customizable designs for various projects. Microsoft and other platforms provide downloadable templates, while HVAC-specific websites offer detailed layouts for residential and commercial use. These templates often include pre-designed ductwork, equipment placements, and zoning systems, saving time and effort. Users can modify them to suit specific needs, ensuring compliance with building codes and energy efficiency standards. They are ideal for architects, engineers, and DIY enthusiasts seeking cost-effective solutions for HVAC system planning and implementation.

8.2 Paid HVAC Layout Plan Templates

Paid HVAC layout plan templates offer advanced features and professional designs, catering to complex projects. Platforms like Microsoft and specialized HVAC software provide premium templates with detailed components, such as custom ductwork layouts and precise equipment specifications. These templates are ideal for large-scale commercial or industrial applications, ensuring accuracy and scalability. They often include additional tools for load calculations and system sizing, making them a valuable investment for professionals seeking high-quality, tailored solutions for their HVAC projects.

8.3 Online Platforms for HVAC Plan Downloads

Online platforms offer a variety of HVAC layout plan templates and resources. Microsoft’s official download center provides updates and tools for HVAC design. Autodesk and other CAD platforms offer detailed templates for professional use. Websites like HVACPlanPro and CADdetails host extensive libraries of downloadable plans. These platforms cater to both residential and commercial projects, ensuring access to scalable and customizable designs. They simplify the process of creating accurate HVAC layouts, saving time and effort for engineers and architects.

Future Trends in HVAC Layout Plan Design

Future trends emphasize smart HVAC systems, IoT integration, and automation, focusing on energy efficiency and sustainable practices to enhance building performance and reduce environmental impact.

9.1 Smart HVAC Systems Integration

Smart HVAC systems integrate advanced technologies like IoT and automation, enabling real-time monitoring and control. These systems optimize energy use, improve comfort, and reduce operational costs. By leveraging machine learning, they predict energy demands and adjust settings accordingly. Integration with building management software enhances performance and simplifies maintenance. Smart HVAC layouts also support remote access, allowing adjustments via mobile devices. This seamless integration promotes sustainability and efficiency, aligning with modern green building standards and user expectations for intelligent, adaptive environments.

9.2 Green Building and Sustainable HVAC Design

Sustainable HVAC design focuses on reducing environmental impact while maintaining efficiency. Green building practices incorporate energy-efficient equipment, renewable energy sources, and eco-friendly materials. HVAC layouts are optimized to minimize energy consumption and lower emissions. Techniques like geothermal heating and natural ventilation are increasingly adopted. Additionally, smart technologies integrate with HVAC systems to monitor and reduce waste. These practices align with global sustainability goals, offering long-term cost savings and promoting healthier indoor environments. Sustainable HVAC design is crucial for achieving LEED certification and meeting modern environmental standards.

9.3 IoT and Automation in HVAC Layout Plans

IoT and automation are revolutionizing HVAC layout plans by enabling smart, data-driven systems. Smart sensors and automated controls optimize temperature, humidity, and airflow in real-time. IoT-integrated HVAC systems reduce energy waste and improve comfort. Automation allows for remote monitoring and adjustments, enhancing system efficiency. Advanced algorithms predict energy demand, ensuring optimal performance. These technologies also enable seamless integration with building management systems, creating a more responsive and adaptive indoor environment. IoT and automation are key to future-proofing HVAC designs for smarter, energy-efficient buildings;

Leave a Reply

You must be logged in to post a comment.